Rheology Modifier

Microfibrillated cellulose (MFC) is a non-Newtonian, shear thinning and thixotropic material. Due to its rheological properties, Celova® MFCs can be used as a thickener, anti-dripping agent, process aid, and stabilizer. While the shear thinning allows good sprayability and application, the thixotropy of the MFC prevents dripping.

Typically, suspensions are structured liquids, which are soft solids that flow. Microfibrillated cellulose can also be described similarly.

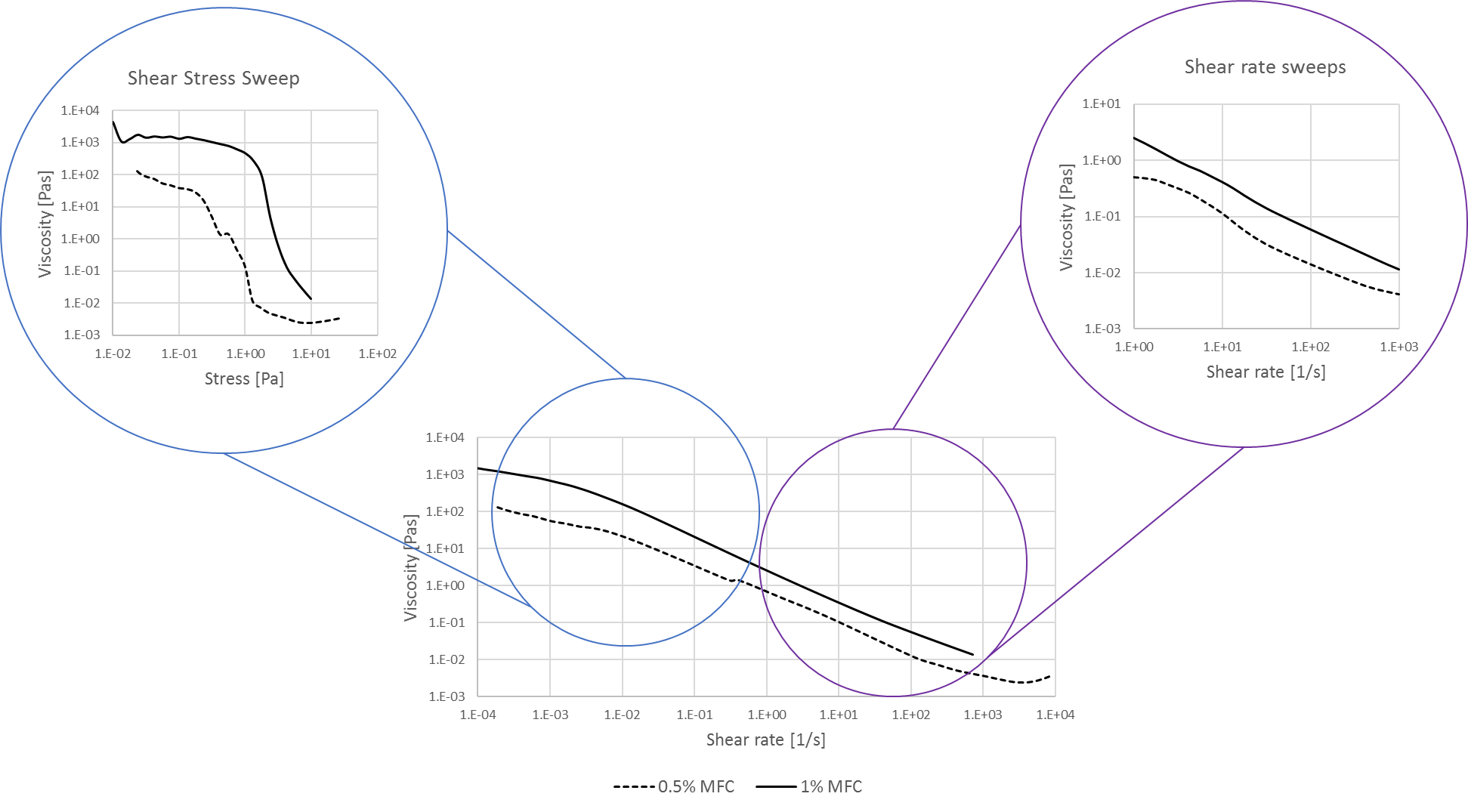

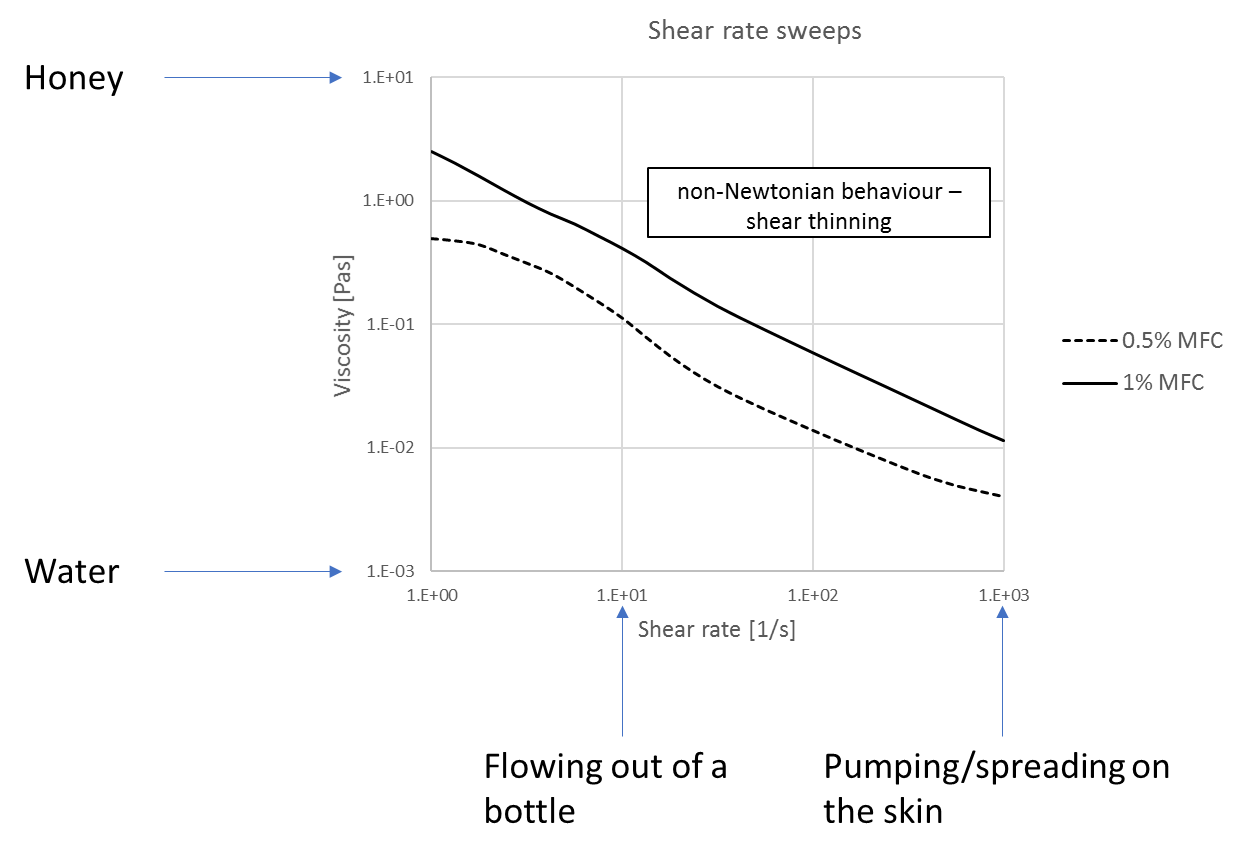

A shear rate sweep of 1% MFC quickly reveals the material’s non-Newtonian shear thinning behavior. While the viscosity of MFC at low shear rates is similar to honey, at higher shear rates, the viscosity drops steeply and is comparable to water.

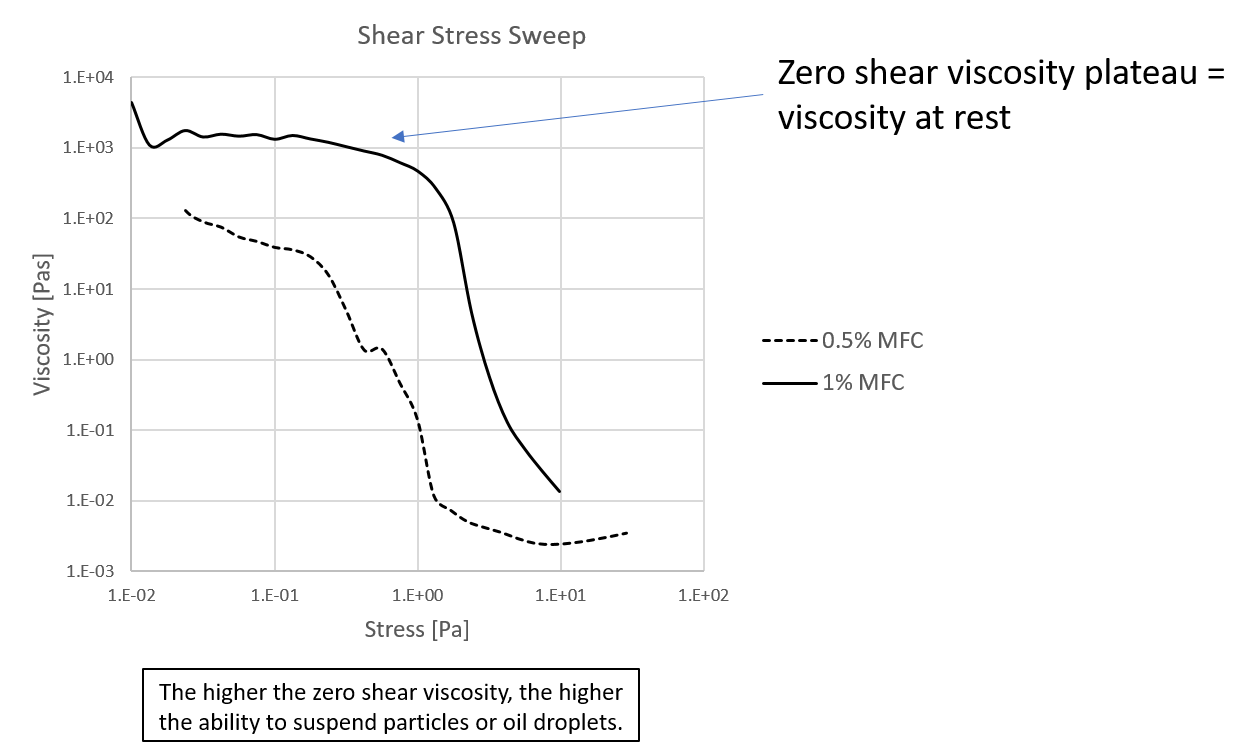

A shear stress sweep can be used to determine the zero shear viscosity plateau of MFC. The zero shear viscosity plateau describes the viscosity at rest and corresponds with the ability to suspend particles or oil droplets. While 1% MFC shows such a plateau, it cannot be observed for 0.5% MFC. That means for suspending properties, it is recommended to use > 0.5% MFC in a formulation if no additional rheological modifiers are used.

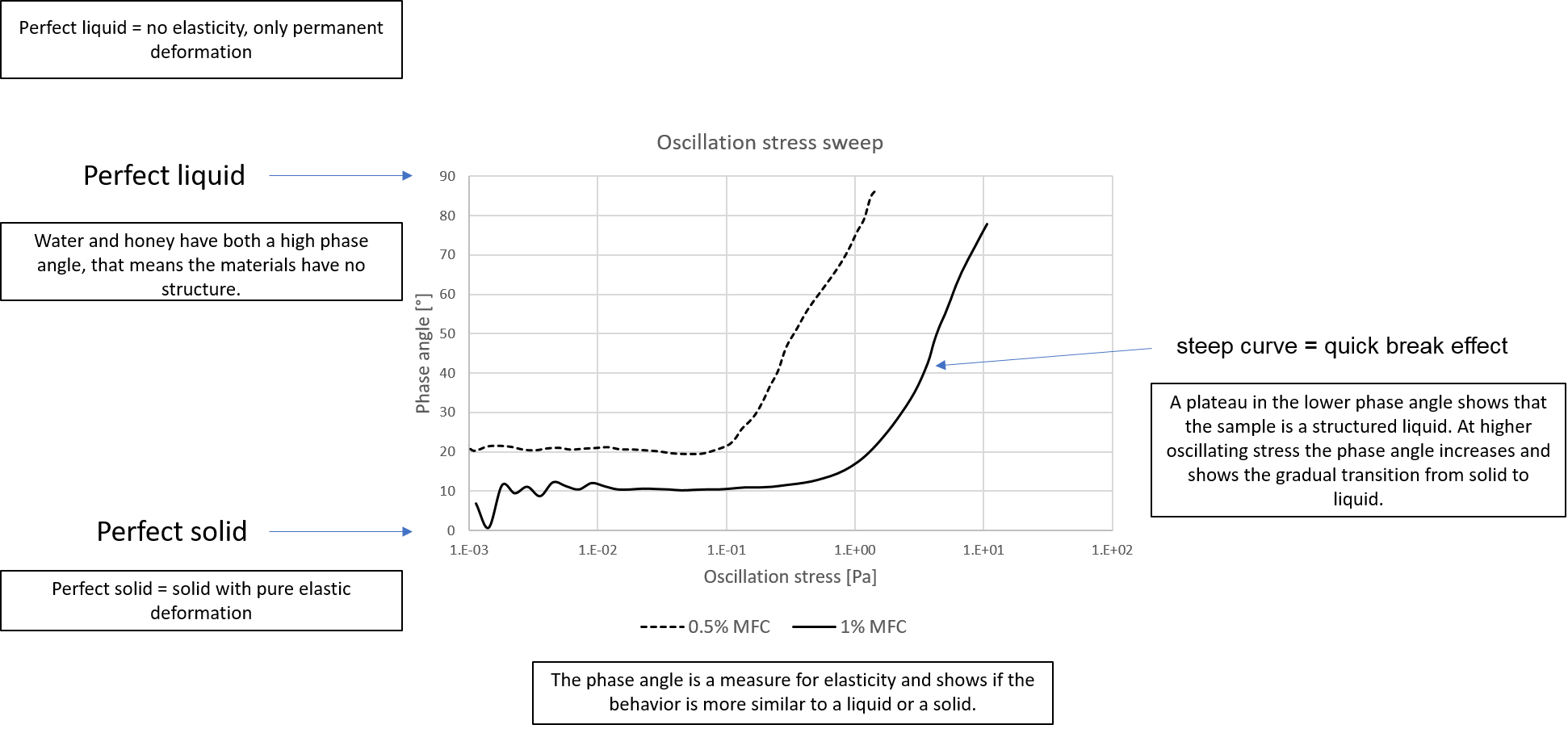

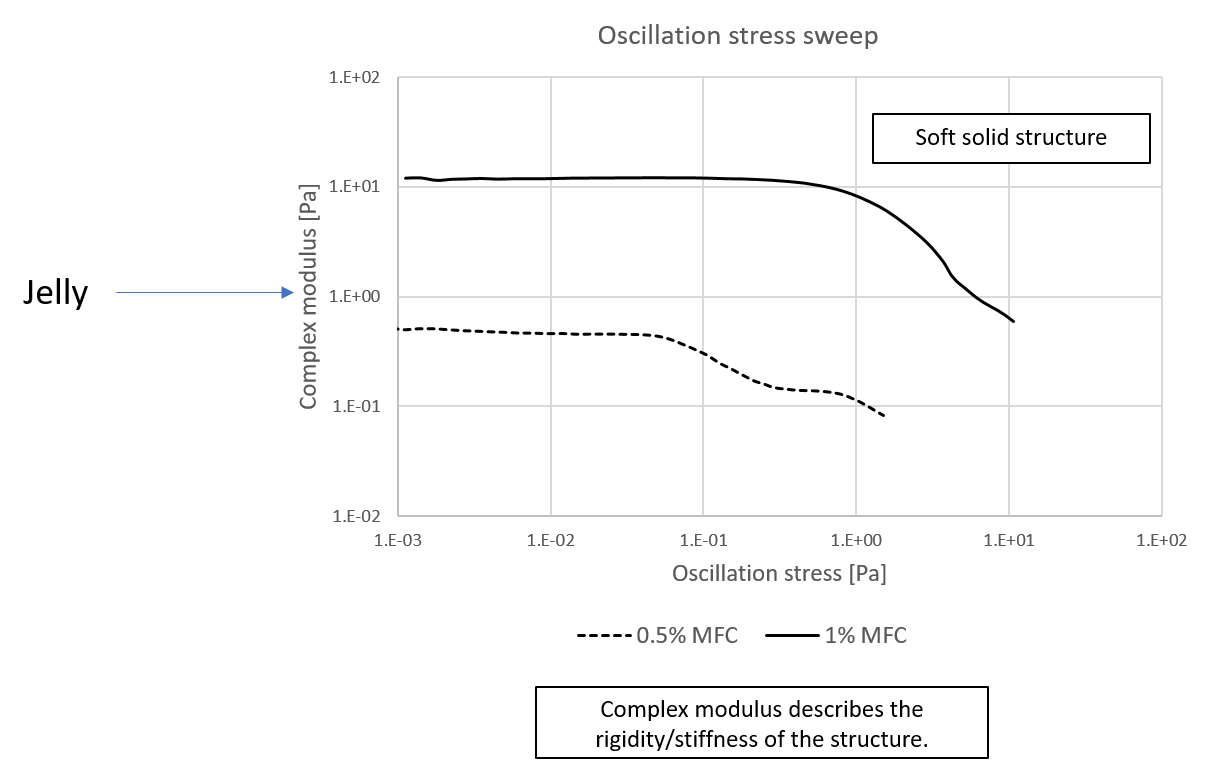

To better characterize the gel structure of MFC, an oscillation stress sweep can be conducted. The complex modulus describes the rigidity of the gel structure. MFC has a soft solid structure according to the values for a concentration of 0.5% and 1%. Furthermore, the phase angle determines the viscoelastic behavior of MFC. The plateau at low phase angles shows that MFC is a structured liquid. A transformation from solid to liquid behavior can be observed at higher oscillating stress. A steep transformation is e.g. desired for quick break effects in cosmetics. That means MFC behaves like a soft solid at rest and transforms into a liquid once shear is applied.